It is easy to understand what you get from most of the sensors in a data recorder.

A GPS offers a precise position, a thermometer measures temperature, and a light sensor detects … well, you get the point.

But the benefits of a built-in accelerometer can be a bit more difficult to wrap one’s head around.

It is, however, from the accelerometer we extract many of the most essential data points in modern data recording solutions.

Below you will learn about some of the most valuable data points from the accelerometer along with their immediate use cases.

What kind of data do I get from an accelerometer?

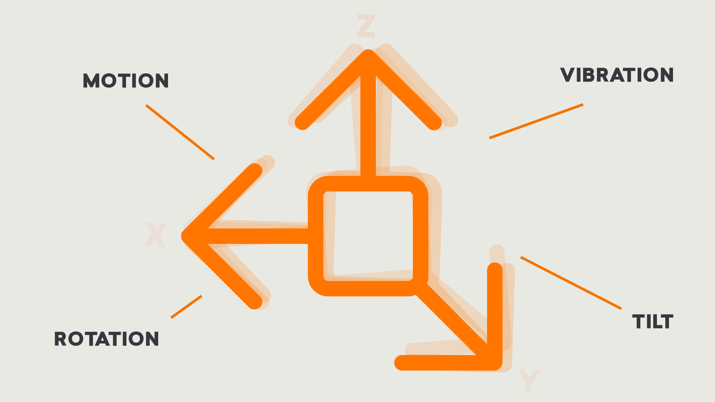

The 3-axis accelerometer in modern data recorders works by measuring any acceleration, in three different directions, of the asset to which it is mounted.

By comparing this input against the gravitational force, we are all surrounded by at all times, it can measure rotation. By combining it with position data, it can measure both movement and changes in movement.

Simply put, this means a 3-axis accelerometer will measure movement, while also sensing from which direction things are moving and at which force.

In theory, it will be able to detect even the slightest of movements and consequently also the hardest and most forceful – until the logical limit of the robustness of its hardware.

With the right firmware and software to manage this impressive data source, a wealth of interesting use cases opens up for both construction and logistics businesses in particular.

The benefits of monitoring movement

A logical use of accelerometer data on movement is to monitor the motion of things that are not supposed to be moving.

An example of this could be theft protection: you can now detect if machines or other assets are moving outside a specified time frame such as outside normal working hours.

Add an automatic software alarm system to alert you if these instances occur, and you have effective anti-theft protection.

Another use case of monitoring motion is to accumulate for how long things are moving.

In this way, you can measure the working hours of machines and vehicles.

Advanced movement patterns to monitor running hours of anything

As mentioned, the 3-axis accelerometer is also able to perceive directional movement. This enables us to see not only that things are moving but also “how” they are moving.

With the right firmware, you can identify specific advanced movement patterns such as vibrations at a certain length or force.

In this way, data recorders can identify the shock of a hydraulic attachment, the vibration from a compactor, or the movement of a crusher.

This opens up for calculating the running hours of these assets individually, as the data recorder will only take into consideration the patterns in which these work and disregard other movements.

The complete report of how your freight is handled

The ability to monitor advanced movement patterns is perfect for monitoring the handling of freight and cargo in logistics and transport operations.

Working as an impact sensor, the 3-axis accelerometer will give you both direction and force of potentially damaging drops. This offers valuable information to determine if freight has been damaged during transport or to prove compliance.

Other uses in logistics and transport include detecting if pallets or assets have been exposed to tilting which could indicate reckless handling or even suspicious activity such as theft.

Another important data point is rotation. You can now monitor if assets that need constant rotation are being handled under the right circumstances.

Accelerometer data combined with other data metrics

It is clear that the data from a 3-axis accelerometer is a powerful resource – both in a construction setting and in logistics during transport operations.

Obviously, the use of this data depends on the quality of the firmware in the data recorders that control the output and the software solutions that interpret and visualize this output.

At Trusted, our firmware and software solutions are designed to tackle the real-life challenges described in this article. We are experts in data monitoring and have a long experience in delivering precise and reliable data for both construction and logistics businesses.

We invite you to share your business case with one of our experts to get started with implementing some of these smart solutions in your business.

We also invite you to click below to learn more about our solution and the possibilities of IoT data recording in your industry.

The accelerometer in a data recorder can measure the movement of the asset to which it is mounted.

The use cases that this data makes available include some of the most popular digital solutions in modern data tracking.

Compliance reports based on correct handling or predictive maintenance based on running hours are both examples of solutions made possible by accelerometer input.