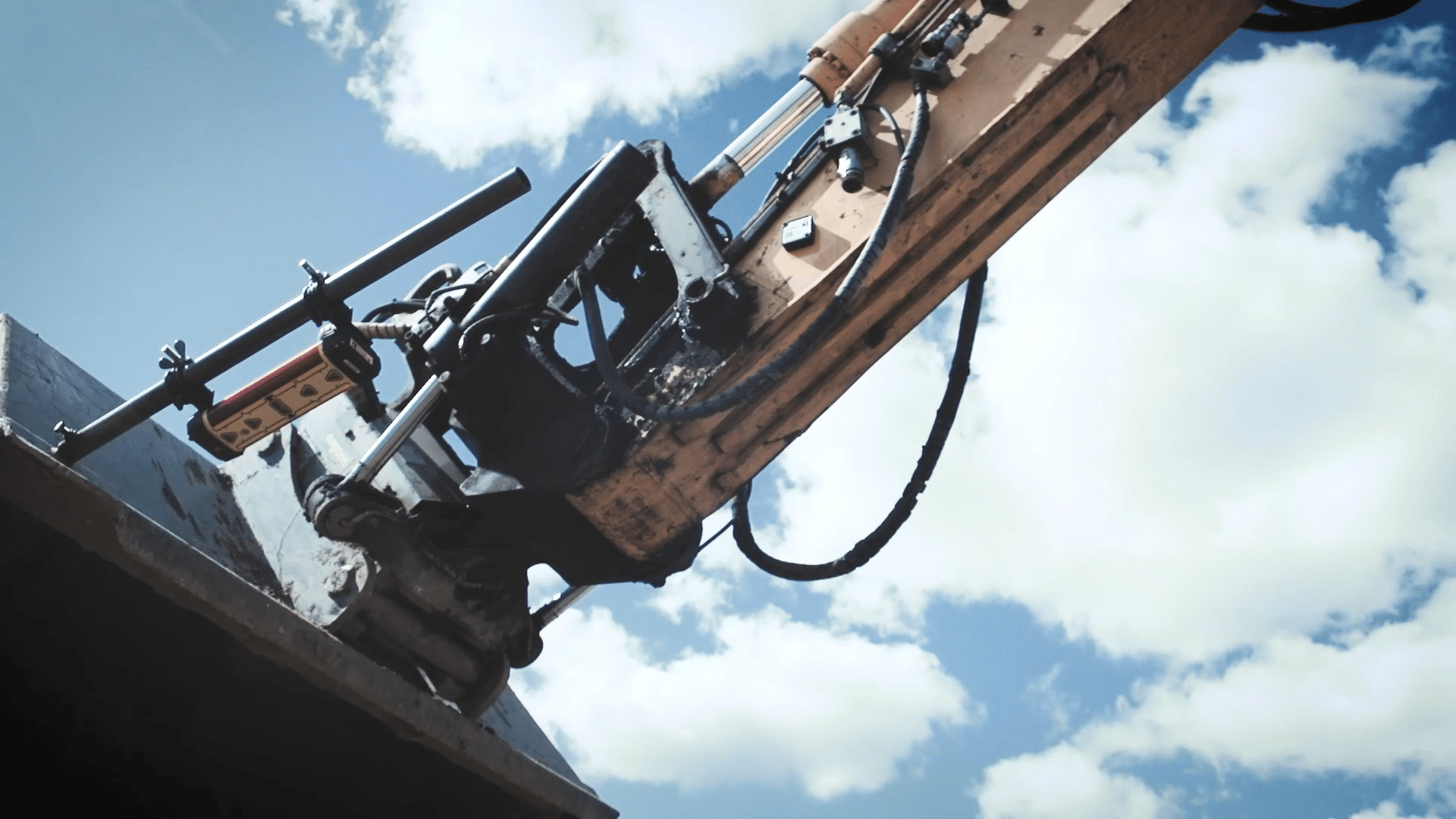

An excavator moves around a demolition site. It turns its heavy hydraulic attachment at a massive concrete block. With a deafening roar of steel against rock, the it breaks the block in half.

Elsewhere, hydraulic cutters rip through fortified concrete walls before bulk pulverizers turn them into gravel.

You would struggle to find a harsher working environment than here.

Hard data: The future of construction is digital

Construction was until recently one of the industries to be the least digitalized. But these years, this is changing rapidly.

While modern construction machines have used data monitoring for a while, the area of excavator attachments is beginning to follow suit.

Producers of hydraulic attachments are now able to offer clients the opportunity to analyze running hours, predict maintenance, and get an overview of their buckets, cutters, and other equipment.

This new development is made possible by impressively durable wireless IoT data recorders that are designed for installation and life under even these extreme circumstances.

Incredibly robust, yet highly advanced

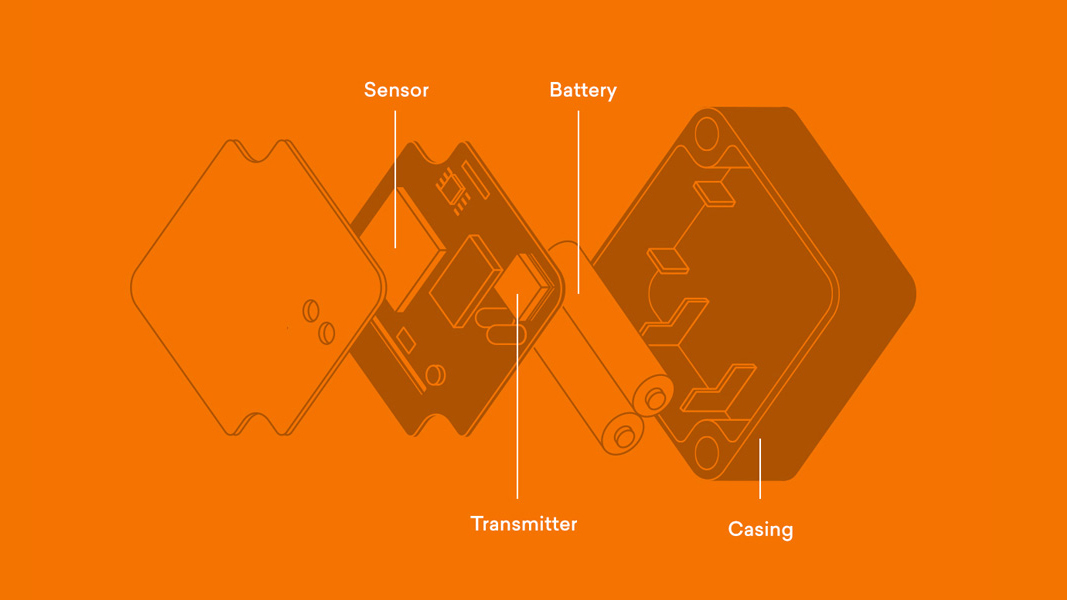

One such IoT data recorder is the Trusted T7 LTE featuring highly advanced sensor technology in an impressively durable IP69k exterior.

It feels robust and puck-like when you hold it in your hand. And if not for the two diodes that sit in the front of the device, you would not even think you were holding a piece of advanced technology.

Encapsulated in a protective shell of epoxy in a nylon cast, the device features an accelerometer, an impressive battery pack, and mobile network technology.

This game-changing design enables the sensors to pick up the slightest of movements while enduring drops and vibrations that would normally be devastating.

An impressive catalog of use cases underlines the durability

That the T7 LTE is a robust piece of hardware is underlined by its impressive catalog of use cases.

“During initial tests, we left a device 50 meters under water for a week, ran another over with a construction roller, while one accidentally was caught in a fire, when a car burned down," Chief Technology Officer at Trusted A/S, Christiane Nico Jensen-Haarup, explains. "And every time, the devices kept transmitting data."

Since then, the T7 range has proven its robustness numerous times under real working conditions.

On one such occasion, a device fell out of the hands of a client who was installing it on a wind turbine 80 meters above ground level. Upon retrieving it, the device was totally unharmed and promptly transmitted data from its new position after being properly installed.

But most telling of the robustness of the hardware is how it has become a preferred data recorder for producers of hydraulic attachment tools.

“To test and configure the hardware for life on hydraulic attachments, we performed an electrodynamic vibration test. Here the hardware passed at even vibration levels in excess of 100 g”, Christiane Nico Jensen-Haarup says.

And as the hardware has been optimized, so has the data solution which will process the sensor input and present it online for analysis.

Data on running hours, use patterns, vibration levels and more

The accelerometer data from the T7 LTE IoT device is transmitted to servers using mobile network technology. In this way, managers can access data without needing to read it manually on the attachments.

The main points of interest are often running hours and the use patterns of the excavator attachments. These two data points could be defined by movement or vibration levels based on certain g-force.

The second option, where the power of the measured vibration defines the running hours, is a game changer when it comes to hydraulic attachments.

This is because the data from T7 devices attached to an excavator moving around a construction site will be separated from the vibrations of a working hydraulic attachment tool crushing concrete and stone.

One can furthermore analyze certain vibration patterns on length or strength to see in the data if attachments are overused or used in the wrong way by drivers.

Delivering the digital hydraulic product that your customers expect

One of the main driving forces of digitalization in construction is that customers and clients have come to expect this feature from their products.

And it is easy to see why clients would prefer a digital hydraulic attachment to a non-digital product, based on the benefits that running hours and use-pattern analysis provide them with.

By knowing the running hours of their hydraulic attachments, they know exactly when to service their product according to the guidelines of your manual. It is even possible to set up automatic service alarms in the software to get a notification automatically.

This way customers can avoid product failure and limit downtime to when attachments require scheduled service checks.

This also saves them the expenses of buying – and waiting for – replacement products to attachments that could have lasted for years longer if used and serviced properly.

And in an inherently non-environmentally friendly setting, the sensible choice for the environment is to insist that one’s assets last as long as possible.

In the end, the benefits of digital products for clients are overwhelming.

I want to know more

To learn much more about the digitalization of the construction industry with IoT data recorders, get the Trusted whitepaper on the topic below.

Here you will become familiar with the technology of IoT data recorders and hear about some of the use cases in the broader context of construction.

For more on the Trusted IoT data tracking solutions dedicated to hydraulic attachment tools, contact Sales Director, Peter Nissen, directly for technical details along with more use cases.

See available times HERE or read more below.

The construction industry is becoming more digital as customers expect producers to deliver a data solution for machines and attachments.

Wireless, durable IoT data recorders are tested to work in extreme scenarios, enabling them to track even hydraulic attachments.

The software based on this data provides customers with solutions to measure and optimize the usage of their products.