Norway is a country famous for its vast stretches of natural beauty.

And weaving through this stunning landscape are miles upon miles of rail tracks.

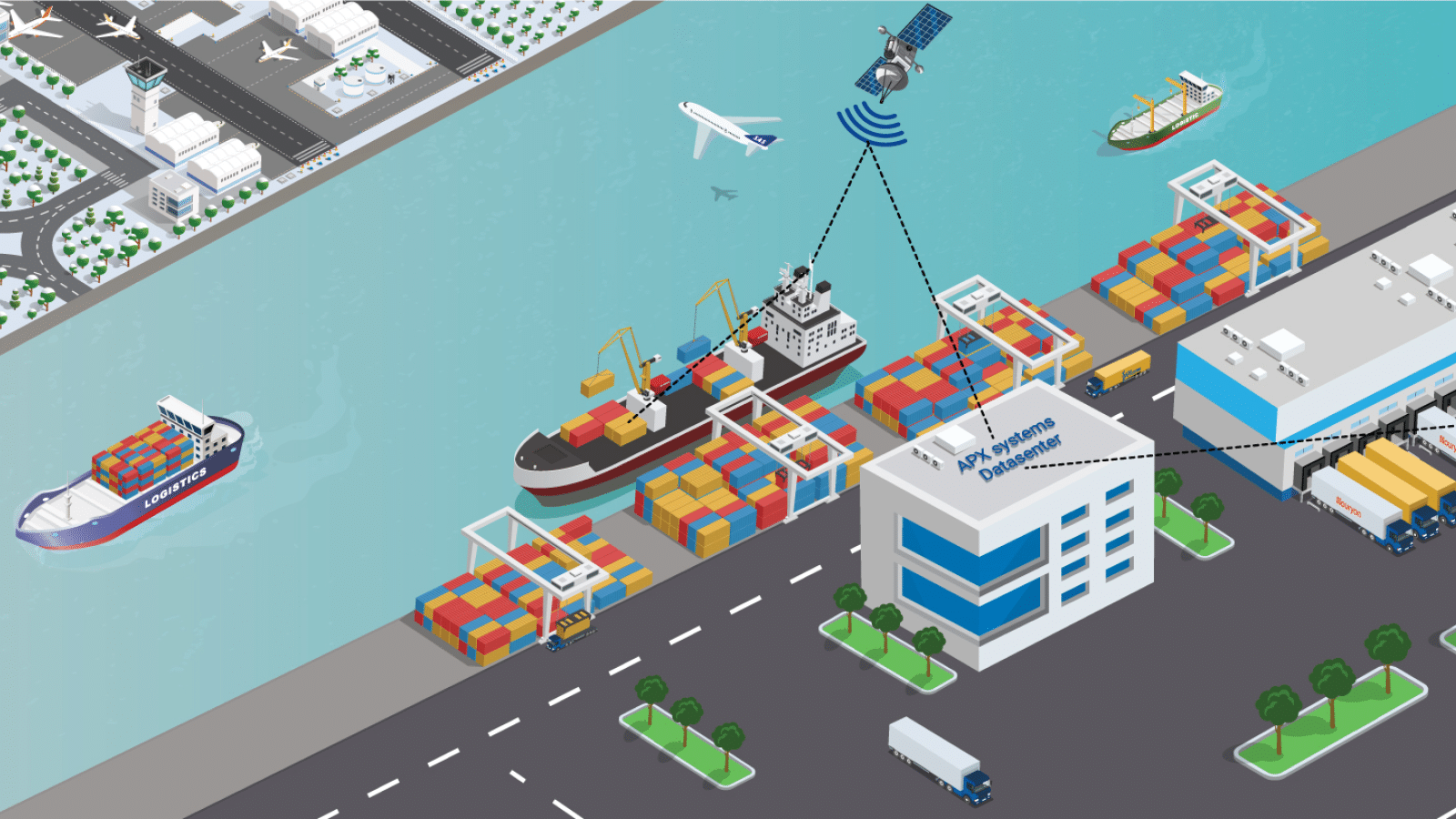

Bane NOR is the state-owned company responsible for the national railway infrastructure – and a user of the Trusted A/S tracking solution.

We talked to Jan-Magne Rakneberg of Bane NOR to learn how the company uses IoT tracking devices to keep track of important snow removal equipment and wagons during the country’s harsh winter conditions.

Never lost. Know exactly where key equipment is.

On the face of it, the purpose for Bane NOR’s tracking operation is clear.

“Our main purpose is tracking wagons and equipment to know where they are,” Jan-Magne Rakneberg says.

He is Application Manager in Bane NOR and part of the skilled team responsible for implementing and installing the IoT devices.

By using the Trusted tracking solution, they have much better control of the location of their assets. This might be a simple fact in theory, but in reality, it is a real time-saver compared to the time before tracking.

“Before,” Jan-Magne Rakneberg says, “tracking needed to be done manually by traveling around or calling infrastructure operators about the equipment“.

Today, finding the equipment is as easy as a few clicks.

Service and predictive maintenance.

But tracking in the rail industry is much more than the X that marks the spot.

“The primary parameter for us is position,” Jan Magne Rakneberg says, “but also motion hours and measuring utilization are important data parameters.”

This is because, for Bane NOR, it is most important to see how to utilize the equipment most effectively.

They do this by using the data in at least two ways. Firstly, for maintenance purposes, but also related to rental of wagons and equipment to infrastructure maintenance vendors.

The large data sets offered by the tracking solution with parameters like actual hours in use or distance covered is a great help when predicting when wagons and equipment need repair.

But another important benefit is the fact that the data is a great way for Bane NOR to keep track of equipment that is being operated by external operators.

A quality solution to stay effective.

Bane NOR has been using the tracking solution from Trusted A/S for about three years and has not experienced any of the IoT tracking units failing them in this period.

“The quality of units is good,” Jan Magne Rakneberg says. “Solid, unbreakable, and at a competitive price,” he adds.

Jan Magne Rakneberg also highlights the user-friendly web solution and the app for use on mobile devices while acknowledging the good support from Trusted A/S as tools that help Bane NOR stay effective.

Furthermore, Bane NOR is performing ongoing evaluations of the actual IoT tracking devices as well.

“We monitor the battery usage on units to see the lifetime of the units,” Jan Magne Rakneberg says and concludes: “Battery lifetime is very good”.

For – as you could imagine – it is important that Bane NOR can trust they have installed hardware that can withstand with the harsh conditions especially in winter in a vast country as Norway.

And here, the Trusted IoT units checks all the right boxes. They were made for challenges like these.

IoT tracking in the rail industry

From the perspective of Trusted A/S, we are proud to be providing the tracking solution to Bane NOR and excited to hear about how they are using their data to stay effective.

We look forward to continuing to develop smart solutions for them to get the most out of their data in many years to come.

And as you can see from the case story above, tracking in the rail industry makes real sense and is a great tool to stay effective.

To read much more about this and to see data from an actual tracking device go to our dedicated page for tracking in the rail sector.

Bane NOR operates the national railway infrastructure in Norway.

They found that the IoT tracking solution from Trusted was the most effective way to monitor their snow removal equipment on parameters like position, distance covered, and running hours.

They highlight hardware robustness and the competitive price of the solution.