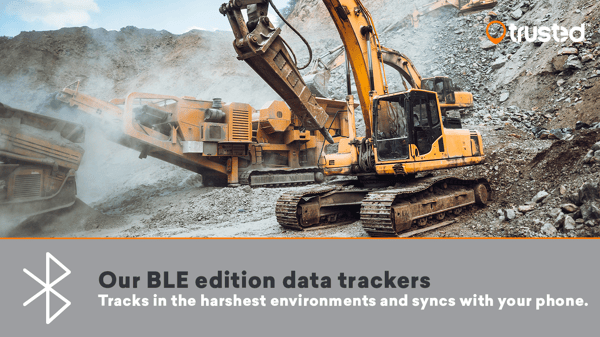

When data tracking of non-powered assets was introduced in the construction industry, not all sectors were able to join in.

Managers of projects in remote quarries, underground, or inside enclosed areas, such as mines, had to wait patiently.

The required mobile network coverage in those locations was simply too poor for even the best wireless devices to transmit data online.

Now, however, the introduction of Bluetooth synchronization to data tracking hardware removes this final hurdle.

This means the digital construction trend is ready to go remote and underground.

Learn below how to track data on construction equipment with Bluetooth in remote areas.

Behind the hype: Data tracking in demolition and mining

The benefits of tracking construction equipment in general and hydraulic attachments in particular are many:

- Running hours

- Use-pattern data of breakers, crushers, and drills

- Predictive maintenance information

This information has never really been available before from these kinds of assets. It will offer managers more insight into the use of their equipment and help avoid breakdowns to essential tools such as breakers, crushers, drills, etc.

The potential is great: avoid downtime, keep projects on time, and save money on unnecessary replacements.

And now, these advantages are moving from projects in cities and rural areas with network coverage to – well – anywhere.

From dust to data: Bluetooth data trackers change the game

In remote pits and quarries. Inside huge warehouses and large concrete buildings. Underground in mines.

Heavy industry work takes place anywhere, and data trackers will monitor how tools are used and track the hours anywhere.

However, solving the issue of getting these insights and features of data tracking to the manager without mobile networks was at first a problem.

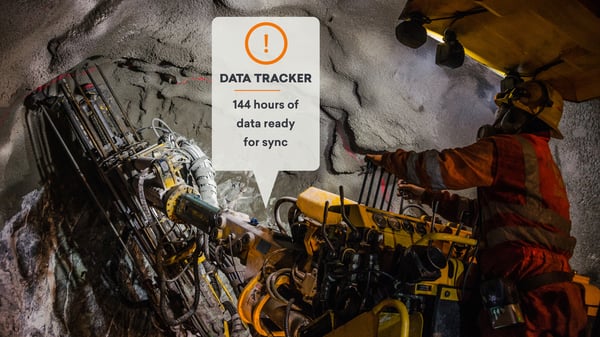

Now, however, new Bluetooth trackers will offer managers to sync the data of devices to the online data portal using a regular smartphone:

- Download and open the data tracking app on your phone

- Connect to and sync with any of your nearby data tracking devices

- Then, take your phone to a location with a data network or WiFi to automatically transmit data online

In this way, the benefits of data tracking will extend to anywhere users need it.

Less downtime, more uptime for the mining industry

The new technology brings a sense of relief to professionals in demolition or mining as equipment breakdowns here are especially critical.

Work often takes place in either remote locations or, in the case of mining, underground. And this means spare parts cannot exactly be delivered day to day.

With insights into running hours and safe use patterns, managers can analyze asset performance and optimize the use of their machines and equipment.

They also have an actual chance to see if and when maintenance is needed.

Everything contributes to less downtime which means more work is done in time.

Giving the construction industry the digital edge

First, we made data tracking of non-powered assets possible in even the harshest of environments, such as on hydraulic tools.

Now, we expand the possibility to enjoy the benefits of data tracking to a united construction industry – wherever work takes place.

This is why we say we are giving construction professionals the digital edge.

To learn how to incorporate digital solutions in your construction business, download our guide: Digitalize your construction business.

And check out the new Bluetooth Low Energy (BLE) data trackers by clicking below.

Data tracking of construction equipment outside mobile network coverage, such as in mines, has never been available before.

But now it is possible to get digitalized with the introduction of Bluetooth Low Energy (BLE) synchronization to data tracking hardware via your mobile phone.

The data can be used to monitor running hours, get use-pattern insights, and predict maintenance on attachments.